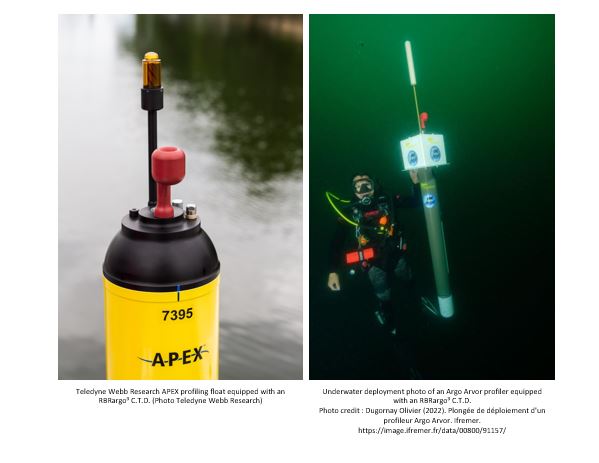

The Argo program is the largest ocean climate monitoring system in the world, providing continuous observations of key ocean parameters through a global array of autonomous profiling floats. In 2018, RBR joined the program’s pilot project to diversify the floats’ CTD sensor technology and introduced the RBRargo3 C.T.D, a low-power, high-accuracy alternative that is reliable even in freezing conditions. After three years of intensive testing and validation in collaboration with the Argo community, the data returned by the RBRargo3 C.T.D were assigned a QC-1 flag, indicating that the RBRargo3 C.T.D is a trusted CTD for the Core Argo program. All major Argo float manufacturers now offer RBR sensors on their platforms.

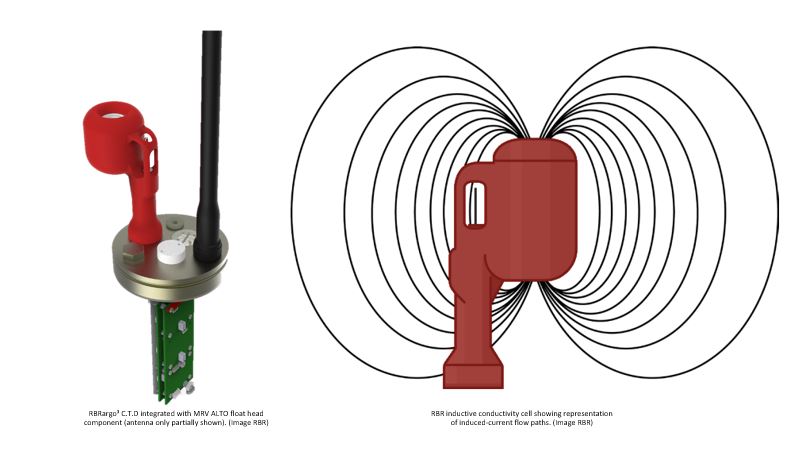

RBR instruments are known for providing high-accuracy measurements using very little power. For a standard Argo profile to 2000dbar, the RBRargo3 C.T.D consumes only 490J, a factor of ten less than other common CTDs. Much of this improvement is due to the design of the RBR conductivity cell. Many common CTDs feature an electrode-based conductivity sensor, which requires a pump to actively circulate water past the electrodes. In contrast, all RBR CTDs are equipped with a naturally flushed, inductive conductivity cell.

As opposed to electrode-based sensors, which require contact between the sensing electrodes and the water and are therefore highly susceptible to even microscopic amounts of fouling, the inductive conductivity cell is unaffected by trace amounts of contaminants such as surfactants and oils. RBR CTDs are therefore well-suited to measurements in near-surface waters, nominally within 20cm of the air-sea interface. These additional measurements allow for better flux estimates to inform ocean models, ultimately resulting in improved predictions of how the ocean interacts with the atmosphere.

Most recently, the RBRargo3 C.T.D was tested for both static and dynamic accuracy and found to be well within the industry-standard specifications for the Core Argo mission. Dynamic effects on conductivity, including dependence on profiling speed of the conductivity cell’s thermal inertia, were characterised and corrected for; these treatments are explained in depth in Dever et al. (2022). The corrections are computed internally on the RBRargo3 C.T.D, and corrected data are streamed to the Argo float. RBR conductivity measurements are calibrated to an accuracy of ±0.003mS/cm with a resolution of 0.001mS/cm, with temperature measurements accurate to ±0.002°C. The accuracy specifications for conductivity and temperature are valid over the range of 0 to 85mS/cm and -5 to 35oC, respectively. The RBRargo3 C.T.D has an accuracy of ±0.05% of the full-scale pressure.

In addition, RBR is expanding into other Argo missions. RBR offers a suite of biogeochemical sensors suitable for integration on BGC-Argo floats, like the RBRtridente three-channel fluorescence and backscatter sensor, the RBRquadrante four-channel radiometer, and the RBRcoda3 T.ODO temperature and optical dissolved oxygen sensor. All sensors feature low power consumption and a small form factor, allowing floats to sample for longer with more sensors. RBR also offers the RBRargo3 C.T.D |deep6k, which is rated to 6000dbar and currently being piloted on Deep Argo floats.

Learn more about the RBRargo3 C.T.D and other sensors at rbr-global.com.

Bio for Daniel Nelson

Daniel Nelson is a Technical Sales Manager at RBR Ltd., based in Tacoma, WA. He represents RBR on the west coast of North America and is the primary account manager for all of the major oceanographic research institutions and agencies in the area. Prior to RBR, Daniel worked in meteorological instrument sales at Coastal Environmental Systems, a subsidiary of Campbell Scientific Inc. He is a graduate of Oregon State University and has a master’s degree in river ecosystems from the University of Birmingham in the UK.